The Chippendale school stands for the very best in teaching furniture design and making.

It means that all our professional course students graduate with the skill to visualise their designs in 3D and with the hand tool skills to turn design ideas into finished pieces of furniture.

But we’ve also now taken on another tutor who, on top of his generalist teaching role, brings with him some exciting new skills.

Andrew Cockerill has been running his own business, Northern Woodwright Furniture, from incubation space at the school from which he graduated in 2017.

He’ll continue to run his business part-time, but is also now part of the Chippendale school’s team.

He has particular skills in computer aided design (CAD) and computer aided manufacturing (CAM).

With the school acquiring a CNC router, he’ll also be able to demonstrate how computers and machinery can work together to, for example, cut or carve wood.

He’ll also be able to show our students how their designs can be brought to small-scale life using 3D printing.

This allows a designer to create a scale model of any piece of furniture, giving the client a tangible sense of what the finished piece will look like.

3D printers use rolls of plastic or wood fibres to create the model, which can then be sanded and stained for additional realism.

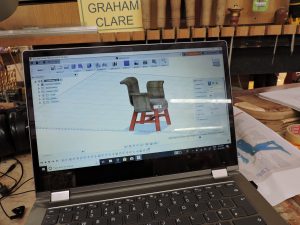

The value of CAD can be seen in this screenshot of Icelander Oli Juliusson’s funky chair (pictured above) which he’s in the process of completing.

CAD allows the piece of furniture to be seen from every angle, enabling the designer to fine-tune their ideas – as well as precisely calculating the amount of wood required.

“While the Chippendale school is all about teaching age-old skills, we also believe in opening our students’ eyes to the potential of new design and making technologies,” said Tom Fraser, deputy principal.

Pictures: Andrew (main) designing his tutor’s workbench, and pictured with Oli and his chair.